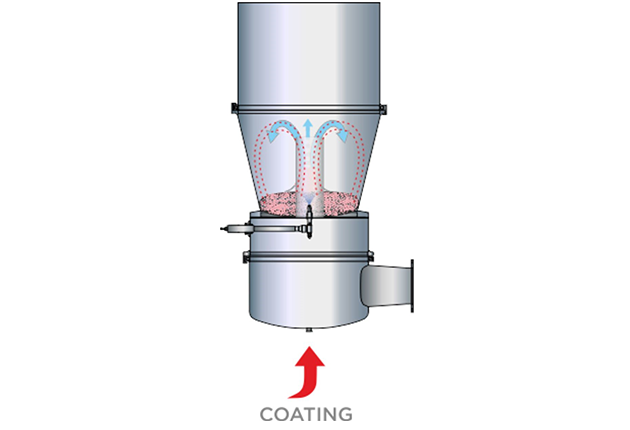

Pellet Coating Systems

Pellet Coating

Lab & Pilot Scale Production

Kevin’s FBS Wurster systems for the R&D & Laboratory applications are ideally suited for process development & evaluation. These equipment offer all the features of production machines, but at smaller scale & with fine control of various parameters. Our equipment offer the possibility of processing materials from 10 grams to 4 kg.

Fluid Bed Systems 10 to 30 kg model

With equipment capacities from 10 kg to about 30 kg, the pilot batch equipment replicates production equipment, with smaller batch processing capabilities. Parameters from the Laboratory Scale equipment can be used to scale up the production to a pilot scale production level. Automation & cleaning systems are offered on these equipment.

Medium Scale Production

Equipment capacities from 50 kg to about 300 kg are offered in this range with robust construction & industrial controls. Equipment is supplied with all necessary features & functions for effective production as well as operator & batch safety. With the increasing need of cleaning, CIP systems are configured & supplied to meet the extensive cleaning & validation requirements. Industrial controls are provided as standard. Based on the equipment configuration & requirement, either a single column or a multicolumn Wurster system is included along with the necessary spraying systems.

Large Volume Production

Fluid Bed Systems, with capacities up to 500 kg are offered for high volume production. With features that offer the highest amount of safety & controls, the equipment is easy to operate & control. The high volume production equipment features a lot of features & automation for easy & automatic handling of materials as well as loading & unloading under closed conditions. The equipment provides very high level of operational stability & ease of use for continuous production. Based on the equipment configuration & requirement, either a single column or a multicolumn Wurster system is included along with the necessary spraying systems